|

|

|

Two Bin Stock Control

We have introduced the Two Bin/Kanban concept into Ostendo, typically used for low-value, high-volume items that still require stock control. Previously, all items were treated the same way (full perpetual control), where stock replenishment requirements were generated based on demand and supply, using re-order quantities, multiples, minimum levels, and history days.

High-volume, low-value items (e.g. consumables) are essential to manufacturing or jobbing environments and must never run out, as this could jeopardize the entire process. However, treating these items the same as higher-value inventory (full perpetual control) requires additional administration.

These consumable items may be backflushed to maintain stock on hand but need to be reordered via Inventory Replenishment to maintain adequate stock levels. Typically, these items are sourced locally and do not have long lead times.

Items marked as "Two-Bin" will be excluded from the Inventory Replenishment and Order Inventory Availability functions. The re-ordering and issuing process is triggered when a bin is emptied via a new screen called "Two-Bin Replenishment."

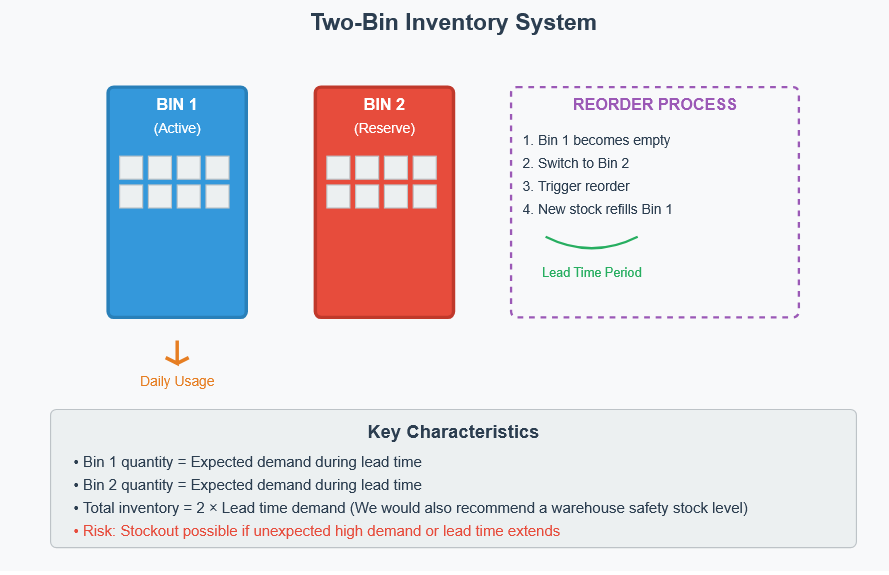

How A Two Bin System Works:

The Two Bin concept uses two bins, one placed in front of the other. When the first bin is emptied, the second bin (which contains stock to cover typical demand over the item's supply lead time) moves to the first bin's position. The empty first bin triggers re-ordering of replacement product. When received, the stock goes into the empty bin and is placed behind the current bin.

This simple concept prevents the factory from running short of product and provides timely notice when more product is required. However, while this process simplifies re-ordering, it can potentially lead to higher stock holdings.

Implementation in Ostendo

To reduce items from inventory, Ostendo currently allows:

- Backflushing items to deplete stock on hand

- Manual issuing of items to deplete stock on hand

Because Ostendo allows backflushing and manual issuing, these transactions must be considered when an empty bin is returned for reordering. We maintain a running total for each bin, determine what has been issued versus the bin quantity, and write off the difference as material usage with a type of "ISSUE."

Each physical bin is defined with its own quantity, which can default to the item's "Re-Order Qty" or use a specific override quantity. The issue warehouse and location for each bin is also required.

Although different locations can be defined for different bins, this is not required. When determining bin issues (upon return of empty bin), we examine total issues for the entire warehouse.

Process Flow

When an empty bin is returned for reordering, a user scans a barcode (or manually enters the bin barcode) into a new screen, which triggers:

- Order Requirements Creation: An Order Requirements record is created to replenish stock for that specific bin quantity. The normal process of generating a Purchase Order from this requirement follows (using the Create Required Orders screen).

- Inventory Transaction: An Inventory Transaction is generated to write off the bin's quantity less any previously recorded backflush or manual issues at the warehouse level. This accounts for other picking or backflushing processes, ensuring we don't over-issue since the last bin re-order.

- Running Balance Maintenance: A running balance for Two Bin inventory records is maintained in a new Two Bin inventory table tracking what has been issued outside the Two Bin replenishment system.

Example Scenario

Item ABC

- Stock on Hand: 2,000 units spread across three bins plus safety stock

- Safety Stock in Main Warehouse/Location: 1,100 units (maintains enough stock to supply each factory bin, including supplier lead time)

Bin Configuration:

- Bin 1: Override Re-Order Qty of 500

- Bin 2: Re-Order Qty of 150

- Bin 3: Re-Order Qty of 250

Scenario 1: Bin 3 Runs Out

When the operator with Bin 3 runs out of stock:

- They return the empty bin to the warehouse and pick up another bin with the same re-order quantity (250)

- The empty bin is scanned to identify the specific bin and its re-order quantity

This triggers:

- Order Requirements record creation for 250 units

- Inventory Transaction to write off the bin quantity less any previous backflush/manual issues

- Running balance update in the Two Bin inventory table

Scenario 2: Bin 1 Runs Out

When the operator with Bin 1 runs out of stock:

- They return the empty bin to the warehouse and pick up another bin with the same re-order quantity (500)

- The empty bin is scanned to identify the specific bin and its re-order quantity

This triggers the same three processes as Scenario 1, but for the 500-unit quantity specific to Bin 1.